DSD – Your Partner for Accident Reconstruction and Crashtests

The Dr. Steffan Datentechnik GmbH was founded in 1990. At the beginning its main task was the development of software for traffic accident reconstruction. Further activities in biomechanics, calculations for structure mechanics and multi body simulations followed. Sled tests and full scale crash tests have been performed for validation and research purposes.

In 1998 DSD developed its own active sled test facility (Hyper G) and mobile data acquisition system.

Since that time, DSD has also worked as an independent testing institute for the automotive and supplier industry.

Currently about 25 employees are working in the areas of software / electronics, testing, construction / engineering and administration.

Based on this development DSD is now supporting 3 major areas.

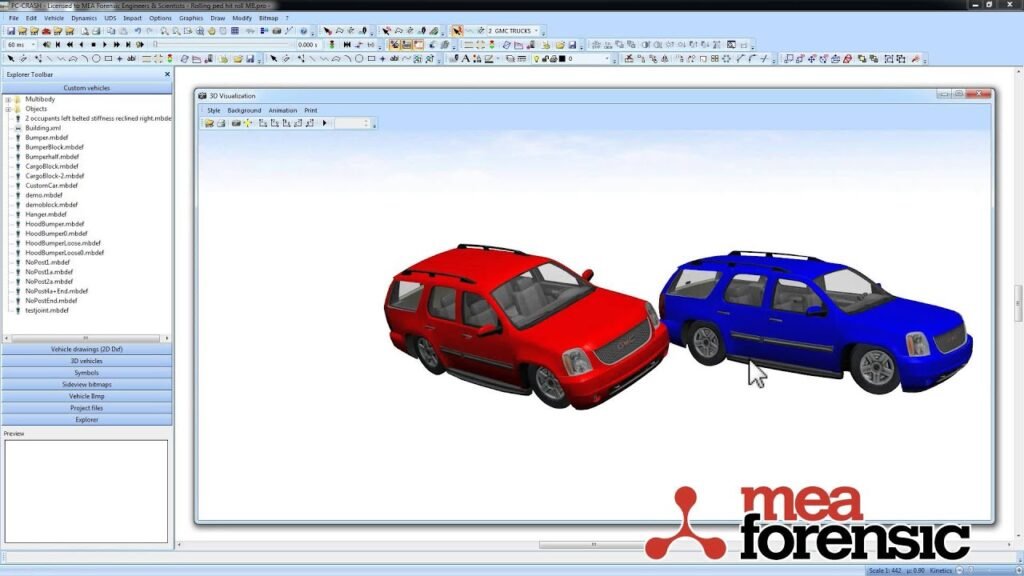

Software development mainly for accident reconstruction

More than 6000 installations worldwide, show, that the software package PC-CRASH has developed as one of the major tools for accident reconstruction. In addition DSD performs more than 1000 accident reconstructions, for court and scientific use, annually.

Crash-Test services

The Hyper-G testing device, installed at DSD is used for crash test services. In addition all important crash testing devices are available at DSD, allowing execution of full scale crash tests up to 40 ton trucks.

Testing tools

ASIS – Advanced Side Impact System

The ASIS is world’s first side impact simulator, which can reproduce multiple intrusion areas at the same time to provide more realistic results than any other simulator systems before. It allows a much more detailed view on the crash phenomenon without causing high costs.

UFO – Ultraflat Overrunable Carrier for experimental ADAS Testing

UFO is a carrier for Soft-Targets and other objects and allows testing ADAS systems of real world scenarios from pre-crash, crash to post-crash phase. The automated control provides a maximum of reproducibility.

Moveable Crashblock

Moveable crash block with mass up to 100 tons is moved by a hydraulic crawler for low contact pressure to the ground.

Crashtest Rig for Electric Energy Storage Systems

Capsuled test chamber for crash investigations under dynamic and quasi-static conditions.

Full-Scale Crash Facilities

An electric engine with maximum reliability drives our full-scale crash facilities. The endless rope system is equipped with an emergency stop for increased safety for the facility operation. The advanced T-track system provides a reduced track width. Our film pit covers are constructed for an optimum view. The mobile crash block provides an optimum flexibility in using the crash facility.

Material & Component Testing Rigs

Based on the intrusion cylinder technologies different material & component test rigs are available. They are customized and used for batteries, belt and other high dynamic load tests.